Join our Telegram

To Follow the UHTG News

Share on telegram

Telegram

Key facts about our installations:

- We are now waiting for the investor's agreements to be fulfilled

- All contracts are signed, but the investor experiences delays

- The moment when our funds arrive, the constructions will start

- We don't have a specific date yet for the work to start

Technology

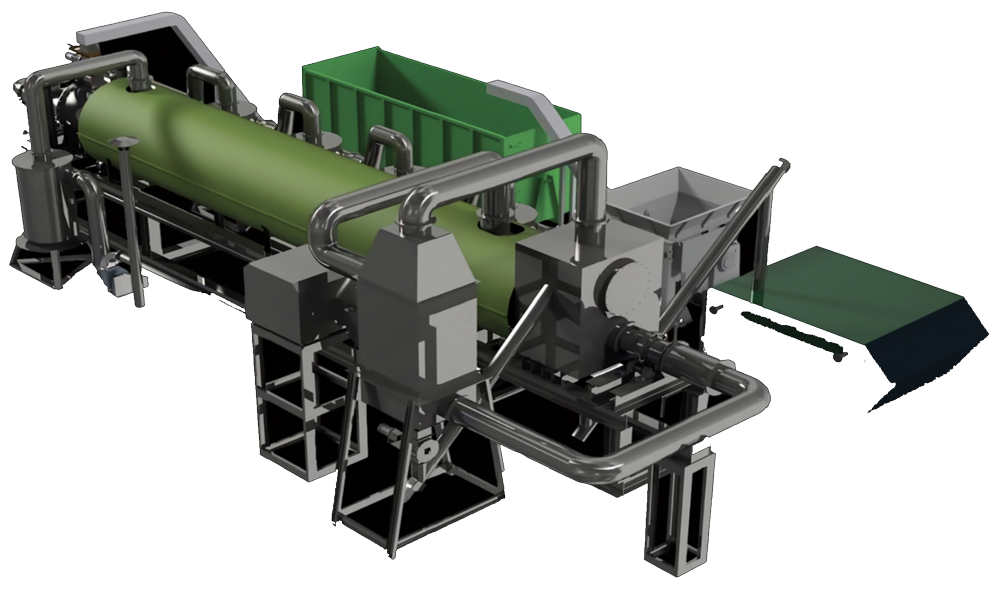

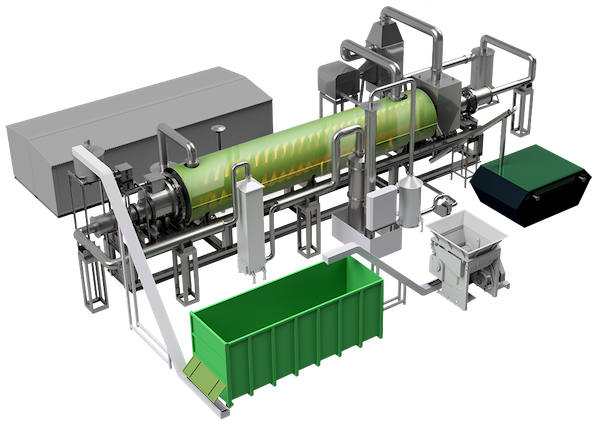

Waste-to-Energy systems

We use Ultra High-Temperature Gasification (UHTG), the next-generation waste utilization process, to produce energy in the form of syngas.

Green

Sustainable

Efficient

Syngas applications

Use of waste heat

Waste heat streams can be used to generate power and fed back into the system, significantly decreasing the power consumption.

Production of electricity

Gasification of waste produces heat and drives a turbine to generate electricity. This indirect approach currently has an efficiency of around 15-27%.

Direct use through burning

Produced syngas can be burned directly, replacing the need of using traditional gas. The caloric value of purified syngas is round 50% of gas.

Hydrogen separation

Syngas is first treated to remove any impurities, primarily water and carbon dioxide. The components are then separated using differences in their boiling points.

Liquid fuels

After purifying, our syngas can easily be converted into liquid fuels, such as methanol, dimethyl ether, synthetic diesel, or gasoline plus (STG+).

Chemicals production

The most commonly used pathways of syngas conversion are Fischer–Tropsch (FT) and the methanol to hydrocarbon (MTH) synthesis reactions.

CleanCarbon Pilot Project

- Pilot Project is being constructed in Fuerteventura, Canary Islands

- Project will consist of smaller T5 unit for R&D and larger T25 unit for main operations

- CleanCarbon is currently purchasing the plot and obtaining the construction licence

- The project is being financed by VC investor and EU subventions

- The picture shows our headquarters, not the actual construction site